WhatsApp)

WhatsApp)

Motor and Electronic Controls. The motor is mounted on the left side of the head. At 8" long X 3 1/2" diameter, it is about twice the size of the minimill''s motor.

Subsequently SAE Air Cleaner Test Code – SAE J726 Specification was updated to include particle size specification limits for test dust relative to the Leeds ...

Ball mill optimization. Dhaka ... Diaphragm condition wear. block Ball size distribution along the mill classify liner Water spray ... Particle size distribution ...

Improving particle size distribution and flow properties of milk chocolate produced by ball mill and blending

More than 12,000+ ASTM standards are used worldwide to improve product quality, enhance safety and facilitate trade. You can purchase individual standards; a volume ...

The Emax is an entirely new type of ball mill for ... High Energy Ball Mill E ... the sample is thoroughly mixed which results in a narrow particle size distribution.

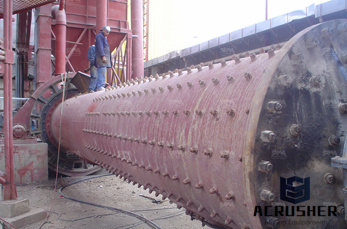

A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for ...

24 Thakur Prasad Yadav . et al.: Mechanical Milling: a Top Down Approach for the Synthesis of Nanomaterials and Nanocomposites . the inner walls of the mill because ...

Tribology glossary index ... Listen to pronunciation

Paul O Abbé Equipment Company is a manufacturer of new Size Reduction Equipment such as Ball Mills, Jar Mills, Slice Mills and more. Call or request a ...

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

Nanoparticles are particles between 1 and 100 nanometres (nm) in size. In nanotechnology, a particle is defined as a small object that behaves as a whole unit with ...

Particle Size Conversion Chart ANSI *A grit size is defined by the distribution of grits retained on a sieve set up that meets the requirements of ANSI Table 2 or 3.

Particle Size Distribution Effects that Should be Considered when Performing Flotation Geometallurgical Testing ... from the classic crushing/rod mill/ball mill

ball mill particle size ... Effect of ball size distribution on milling rate. where x i is the upper size of the particle size interval i under consideration; ...

Combustible Dust Explosions news reports and articles to help industry identify hazardous conditions and mitigate them through knowledge and reference resources.

Superior flexibility. Obtaining a specific particle range and distribution is often the primary objective of a size reduction milling operation.

The history of technology, history of science, history of inventions, the scientific revolution, the industrial revolution, the internet, space, communications ...

ball mill grinding and particle size distribution. Particle Size Reduction – Ball Mills, Continuous Systems Open Circuit Grinding ... limestone ball mill particle size.

AVEKA%u2019s ISO 9001:2008 certified facility features both media particle grinding and milling equipment including ball mills and bead mills, and medialess particle .

Pharmaceutical particle technologies: An approach to improve drug solubility, dissolution and bioavailability

Ball mill Wikipedia, the free encyclopedia. The ball mill is used for grinding materials such as coal, ... Size: The smaller the media particles, the smaller the ...

The influence of grinding conditions on the production of fine particles and the width of the particle size distribution produced during ball mill grinding was ...

Pin mill is a kind of milling equipment that can break up cellular materials selectively without damaging the starch granules. It consists of two horizon...

WhatsApp)

WhatsApp)