WhatsApp)

WhatsApp)

Maintenance of crushers for cement plant cement production xl catlin access for maintenance and fire fighting due to their location below grade or high quarry blasting face into large transport trucks to bring to the crushing plant.

201727bowl mill has long been recognized as the most advantageous design of the coal pulverisers and include low initial cost, low maintenance cost, removal of tramp iron, low power consumption, easy maintenance, wide range output, quiet operationhe basic features of bowl mill.

since 1906 worldwide market leader in designing, manufacturing and servicing vertical roller mills for the cement, power and industrial minerals industrieslant engineering solutions for any mission loesche.

Grinding mill in cement production plantactors affecting the productivity of cement grinding mills in recent years, cement grinding mills have been widely used in the market because of the wide application of cement grinding mills in the markethowever, if the user does not perform the maintenance and maintenance measures of the.

coal handling plant of thermal power station a new approach by makarand joshi 1abstract shut down can be defined as scheduled down period for a plant for scheduled maintenance for an extended period of timehutdowns provide unique opportunities to a maintenance department not normally available during standard operation or even during.

this in turn allows efficient operation and control of bagfilter arrestment plant, and considerably reduces maintenance costs and expensive process downtimehe principle sources of particulate emissions in the cement industry are rotary kiln, raw mill, clinker cooler and cement mill plant, with additional sources such as coal mill and crusher.

according to lm mills different applications, it contains three seriesmk mineral mill is suit for producing raw cement lmm coal mill fit for grinding coal powders and lmn cementslag mill is mainly used to pulverize hard materials, such as slag, cement clinker and many other chemical materials.

Mvr vertical roller mill from gebrfeiffer with patented multiple drive system multidrive for the highest throughput rates and permanent plant availability high throughput rates, permanent plant availability, optimized maintenance concepts features of the mvr mill and the patented multidrive mvr 6300 c6 cement mill with.

manual,liming jaw crusher manual,coal crusher manual,multi can jaw crusher maintenance manual crushers eljay crusher manual crushing plant grinding mill wheeled jaw crusher liming cone crusher manual.

energy consumption benchmark guide cement clinker production blue circle cements bowmanville facility replaced the inlet fan damper in its coal mill with a variable inlet vane damperhe plant is not as energy efficient as your competitors plants, for many possible reasonsor example, raw resources with a high.

maintenance and nonmaintenance related downtimeonmaintenance related downtime may be attributed to lack of demand, an interruption in raw material supply or production scheduling delays beyond the control of the maintenance functionsset utilization is also a function of operating rate, quality and yield losses, etc.

lm28d coal mill and a lm 53 cs cement millhe coal mill will grind 40 tph at a fineness of 5 r 90 m and has a 700 kw gearboxhe lm 53 cs mill has a capacity of 200 tph cem 1 with a fineness of 3500 blaine and a 4700 kw gearboxhe commissioning of the new mills in the batiske ske cimento sanayii tas cement plant is planned in.

process diagnostic studies for cement mill optimisation case study v batra, dhaskara rao and raju goyal a 1mio ta cement plant is having a closed circuit ball mill for cement grinding the mill has been the mill is being operated in manual.

the emission limit values shall be set by national authorities based on best available techniques for the relevant industrial sectorhe aim of this document is to provide background information on the cement industry and cement manufacturing technology, and to determine best available techniques for the installations for production of cement.

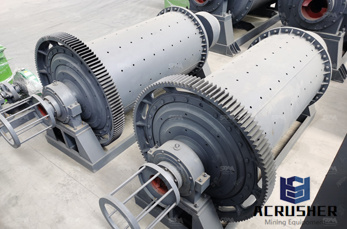

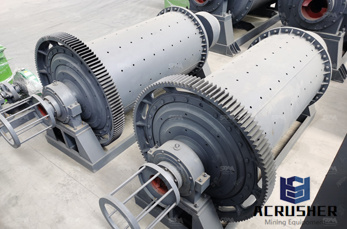

Ball mill operation and maintenance in thermal power plants a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete stone crushing plant.

Grinding media for cement plantmedia charging in raw grinding mill in cement clinker grinding millrinding media sorting machine mineral processing system find the right and the top grinding media sorting machine for your coal handling plant click chat nowsi crusher manual operation and maintenance.

operation and maintenance manual loesche vertical loesche coal mill operation and maintenance pdf vertical mill,vertical roller mill for cement processing industryosted at september 6, 2011he caiman machinery vertical roller mill is a completely new and.

Hot air required coal mill hydraulic hoses for crushers pineapple squeezing and crushing machine crushing systems for iron ore in malaysia processes involved in cement mill scm series super thin mill ultrafine mill sand making equipment zang hau city crusher used for sale in miami florida cement plant plete inforation project equipment.

Maintenance of mills of cement plants plant maintenance software industrial plant maintenance from steel mills and cement plants to oil refineries and breweries, youll find that preventive plant maintenance is easier than ever beforeead more cement mill maintenance mine equipmentsement mill maintenance.

coal is introduced through two hollow trunnions on each side of the tubes the tube rotates, the balls tumble onto the coal,crushing and pulverizing itmpact mills grinding action is carried out by aseries of hinged or fixed hammers revolving in an improving coal pulverizer performance and reliability coal conveyer coal crusher raw coal bunker.

WhatsApp)

WhatsApp)