WhatsApp)

WhatsApp)

ATTRITORS AND BALL MILLS HOW THEY WORK Robert E. Schilling, M. Yang UNION PROCESS INC. Akron, Ohio Presented by Robert "Bob" Schilling Presented at the .

chart for critical speed of ball mill; critical speed equation in a tumbling mill; radius of ball and mill in critical speed; critical speed of mill;

/S"1 International Mining Congress and Exhibition of TurkeyIMCET 2003, (c 2003. ISBN The Effect of Fraction of Mill Critical Speed on Kinetic Breakage ...

TECHNICAL NOTES 8 GRINDING R. P. King. 82 ... The critical speed of the mill, ... Figure Effect of mill filling on power draft for ball mills.

critical speed ball mill. critical speed ball mill The following is the latest product, the specific details click on image consulting product, you can get 50% off ...

Running the correct PROMAX solid carbide end mills at the proper speeds and feeds is critical to obtaining the best production times and tool life.

what is the feed rate for ball mill and the . Cement mill Wikipedia, the free encyclopedia Ball mills are normally operated at around 75% of critical speed, so a ...

AIR CONDITIONING SOLUTIONS FOR THE STEEL AND METALS PROCESSING INDUSTRY HDT Global 30500 Aurora Road Suite 100 Solon, OH 44139

information on ball mills This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their .

End mills (middle row in image) are those tools which have cutting teeth at one end, as well as on the sides. The words end mill are generally used to refer to flat ...

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

Paul O Abbé Equipment Company is a manufacturer New Steel Ball Mills and Milling Equipment. Call or request a quote to get started.

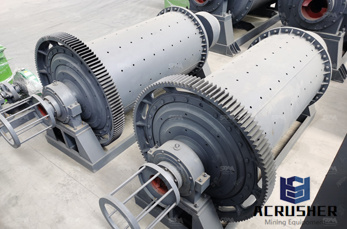

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

Intro: Use a Treadmill DC Drive Motor and PWM Speed Controller for Powering Tools. Power tools such as Metal cutting mills and lathes, Drill presses, bandsaws ...

critical speed of a ball mill and ball size – Grinding Mill . Posted at: July 30, 2012. Ball mill – Wikipedia, the free encyclopedia The critical speed can be ...

A cement mill (or finish mill in ... Ball mills are normally operated at around 75% of critical speed, so a mill with diameter 5 metres will turn at around 14 rpm.

Derivation of critical speed of grinding mill – The QA wiki. What is critical speed of a SAG mill? The critical . is two latticetype ball mill. The materials ...

Ball Mill manufacturers in Mill critical speed design in India India ball mill manufacturers provides you the ball mill and critical speed for ...

The Critical Speed is used for the determination of ball mill ideal operating speed. But for comparison, rod mills would operate between 50% to 95% of the critical speed.

what is critical speed of ball mill. ... Critical Speed Of Ball Mill,Crusher Mills, Cone Crusher ... critical speed of a ball mill and ball size Grinding Mill Posted ...

34 The European Journal of Mineral Processing and Environmental Protection Vol. 2, No. 1,, 2002, pp. 3439 Technical Note Why is the Bond Ball Mill ...

The Satirist: America''s Most Critical Journal an amazing collection of satires, satirical news, book reviews, movie reviews, essays, poems, and fiction.

Critical Speed Of Ball Mill, Wholesale Various High Quality Critical Speed Of Ball Mill Products from Global Critical Speed Of Ball Mill Suppliers and Critical Speed ...

Flutes Spiral cutting edge on the end mill. 2 and 4 flute end mills are the most commonly used. 2Flute Allows maximum space for chip ejection.

WhatsApp)

WhatsApp)