WhatsApp)

WhatsApp)

cement manufacturing process flow sheet. Cement Manufacturing Process Flow Chart. Cement production process can be summarized as a two mill burned, that raw ...

The free encyclopedia for UK steel construction, covering steel design, Eurocodes, steelwork costs, thermal mass, fire engineering, embodied ...

Paint canning is a completely automated process. For the standard 8 pint paint can available to consumers, empty cans are first rolled horizontally ...

Special Economic Zone at Villayat, District Bharuch, Gujarat Jubliant Infrastructure Limited

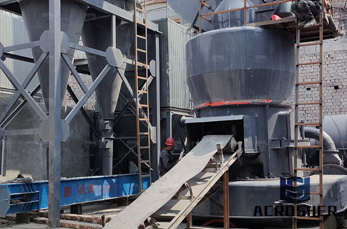

In the cement manufacturing process, most material must be broken, such as limestone, iron ore, clay and coal etc. Limestone is the main raw material for cement production, each producing a ton of clinker needs about tons of limestone, more than 80% of raw material is limestone.

MECS technology provides flexibility to allow process optimization and maximize the return on investment for a given set of economic conditions.

Portland cement can be made by following two different processes – a dry one and a wet one. The manufacturing process has moved on significantly since bricklayer ...

Beautifully designed chart and diagram slides for PowerPoint with visually stunning graphics and animation effects

Understand Cement Production ... 5 Cement making today: the process flow chart ... This block diagram of clinker, cement and concrete manufacturing is shown alongside

Above the operator Logs In to start the process: The next few pictures that follow show features of CELLS and these example pictures used are for

cement manufacturing flow diagram [ 7331 Ratings ] The Gulin ... Cement manufacturing process components of a cement plant from quarry to kiln to cement .

Process flow diagram for portland cement manufacturing. ... The heart of the portland cement manufacturing process is the pyroprocessing system. This

Manufacturing the cement kiln. Most Portland cement is made in a rotary kiln. Basically, this is a long cylinder rotating about its axis once every minute or two.

Environmental, Health, and Safety Guidelines CEMENT AND LIME MANUFACTURING APRIL 30, 2007 4 WORLD BANK GROUP • Developing a staged combustion process .

Cement is the basic ingredient of construction and the most widely used construction material. Its manufacturing includes extraction, proportioning, grinding,

Lehigh Portland Cement is a versatile construction material that is widely used for commercial concrete. Cement is the binding agent for concrete.

Introduction At the time The Oregon Recycling Opportunity Act was passed, it set up a statewide system for managing solid waste that was called the most comprehensive ...

Process manufacturing is the production of goods that are typically produced in bulk quantities, as opposed to discrete and countable units. Process manufacturing ...

Sep 17, 2013· This video provides an overview of how to perform Critical Path Method (CPM) to find the Critical Path and Float using a ...

Complete package that includes: a) machine simulation teaches the student the setup and operation of CNC machines. b) CNC program simulation and gcode debugger ...

cement process flow diagram. CEMEX BANGLADESH | CEMENT BASICS ... Wholesale Various High Quality Cement Manufacturing Process Flow Chart Products from Global Cement.

Table 2: Composition of portland cement with chemical composition and weight percent. When water is added to cement, each of the compounds undergoes hydration and ...

Composition of cement. Introduction Portland cement gets its strength from chemical reactions between the cement and water. The process is known as hydration.

Cement manufacturing process components of a cement plant from quarry to kiln to cement mill.

WhatsApp)

WhatsApp)