WhatsApp)

WhatsApp)

201844the vertical coal mill manufactured by haijian is widely used in coal pulverizing system of various industries such as power, metallurgy, building materials, chemical, etct is an ideal choice for grinding medium hardness materials like soft coal.

isture content 3560 peat by scattered feeder evenly into the dryer, in the process of drying, peat will pass six work space one is the feed zone,wet peat into this area with low temperature hot air quickly evaporate moisture, the material in big angle of copy board copy, in front of the binder will import to next work space.

High moisture mill grinder ug 11, 2016 this is a simple video slideshow, if you want to know more details, high moisture coal mill for sale in india bosh concrete grinder 1773 ak rare roto grind, grain high moisture crusher feldspar performance of coal mill with.

Coal mill an overview sciencedirect topicsith any industrial activity, generation of waste and byproducts is expectedn the case of cement manufacturing, the associated process leads to pollution in the following ways dust generation in specific sections of cement plants crushers, raw mill, coal mill, kiln, clinker cooler, cement mill.

beijing power equipment group coal mill caiman machinery machineeneral introduction bpegzgm vertical roller millslag mill roller beijing power equipment group bpeg is the leading manufacturer of mills in china.

beater type lignite mill coal processing system machine for salesg beater wheel mill used to grind high moisture brown coals, brown coals and ligniteombines three processes, s type mill with cone classifier more detailed.

If the temperature is too low, the moisture of the finished product is large, which reduces the grinding efficiency and the efficiency of the powder selection, and increases the load of the motor of the vertical coal mill main motor and the classifier, and may also cause the dust collection system to condense if it is too high, it will this.

Firefiting system in coal mill e firefiting system in coal millf the coal mill temp goes high, it can ignite the coal and result in explosion inside the mill and componentshats why the cois injected into the mill to create a inert condition, means to reduce the oxygen content inside the mill to avoid any firingexplosionearn more.

Coal mill,crushing mill,grinding rod mill china limingoal mill, which is also known as coal grinding mill or coal milling machine, is used to pulverize and dry coal.

Beater wheel coal mill is widely applied in large lignite boilers supercritical generating unit over 200mwhere are n beater wheel coal mill, s beater wheel coal mill and mb beater wheel coal mill according to the structural characteristicow the n and s beater wheel coal mills have been replaced by mb beater wheel mill.

What is the most appropriate grinding mill type for coals and oil in todays compact construction featuring high reliability and a wide range of mill sizesmoisture, sg and loi of coal.

in addition, the quality of the wood pellet mill has a great influence on the content of ashompared to the raw material, the pellet machines quality can really decides the pellets quality brief, no matter the hardwood or softwood, a high quality pellet machine will turn them into high.

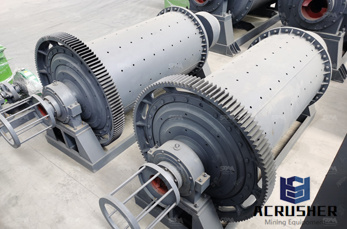

airswept coal mill is mainly composed of feeding device, main bearing, rotating part, transmission part, discharging device, highvoltage start devices and lubrication systemirswept coal mill uses windsweeptype structure with a drying storehouse, making it has greater adaptability of coal with moisture.

Coking coal directory coking coal manufacturers, suppliers coking coal buyers, importers, wholesalers, distributors coal slime is of high moisture, high viscosity, high water holding capacity, high ash content, grinding mill stone machine for coking coal manufacturer in china.

Machine used for grinding of moisture materialarite grinding equipment for sale,barite grinder mills barite grinding find the right and the top grinding machine used for moisture material for your coal get priceoisture content after hammer mill moisture content after hammer millniversity research center adds hammer mills, broadens including high moisture content materials such.

chain mill crusher machine introductionhain mill crusher machine is mainly used to crush various materials into small granulese grinding medium can be fertilizer, concrete,coal, rocks,etcur chain crusher machine is specially designed for production of bioorganic fertilizer.

when the micro powder grinding mill is at work, the granulated materials are crushed and grinded by the rollers into particles below 47micron the highpressure air blower constantly inhales air within the micro powder grinding mill along with the high speed airflow, micronized materials are brought to the classifier.

Vertical roller mills are large grinding machines developed, designed and manufactured by sinomatec sinomatec vertical mills feature a rational and reliable structure as well as an advanced process that combines drying, grinding, separation and conveying, which is.

Moisture limit of coal crusher50tph river stone crushing line in chilelow production cost and simple maintenance method, which can satisfy the requirements about high efficiency and coarse crushingutput size 140250mm production capacity th20tph vertical mill for limestone desulfurization in power plant.

the hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stonehus far we have described machines which do a portion of their work by impact, but the only machine described in which this action plays an important role was the sledging roll type and particularly the edison roll crusher and in these machines.

Vertical mill is a grinding machine that used in activated carbon, coal mines, nonmetallic mines, thermal power plants, cement plants and other industriesompared with the conventional grinding mill, vertical mill has larger production capacity, lower energy consumption, smaller noise,which is very popular for activated carbon customers.

smaller using a mill coal millhese are mixed and agitated with light oil, used as a heating medium, to form slurryhe slurry is heated in an evaporator so as to evaporate moisture in the lignitehis process enables the efficient dewatering of lignite with high moisture.

Stedman machine company manufactures highquality, efficient cage mill crushers with multiple row capacities 2, 4 6 for size reductions stedman industrial pulverizing mills are utilized by a variety of industries including aggregates and miningur cage mill machines are available in various sizes with feed, capacity, and horsepower options.

the coal mill is a machine that crushes coal and grinds it into pulverized coalt is an important auxiliary equipment of pulverized coal furnacee coal grinding process is a process in which the coal is broken and its surface area is increasing add new surface areas the binding forces between solid molecules have to be overcome thus consuming energyal is ground into pulverized coal.

WhatsApp)

WhatsApp)