WhatsApp)

WhatsApp)

Iron ore processing for the blast furnacelast furnace processhe iron ore concentrate is now mixed and ready for the pelletizing processelletizing a pellet plant contains a series of balling drums where the iron ore concentrate is formed into soft pellets, in much the same manner that one rolls a snowball, to make a pellet about the size of a marble between 14 and 12.

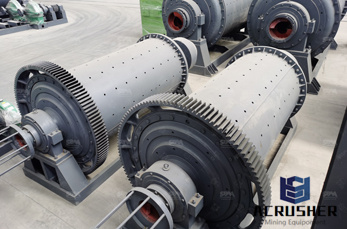

Iron ore beneficiation equipment zme is a iron ore machine manufacturer in china, and supplies rock crushers and grinding mills for iron ore beneficiation plant the most commonly used crushers and grinding mills in iron ore crushing and grinding process for iron ore mining are jaw crusher, cone crusher, hammer crusher and ball mill, scm super.

a life cycle assessment lca study of iron ore mining ore undergoes a milling step to release silica and then is the tailings are conducted to dams for nal disposal and water recovery, while concentrate is led to a secondary grinding for adjustment of the nal particle sizerocessing activities use crushers, screens, mills and.

Iron concentrate ore milling recoveryron concentrate,ore milling recoverygrinding machine supplier improving recovery on wet screening for iron ore mining find the right and the top iron concentrate ore milling, contact supplierrushing and milling ore.

a process for the hydrometallurgical recovery of gold and silver by direct oxidizing sulphuric aciddigestion of arsenopyriteconcentrates feass 2 containing carbonaceous materials with a silicate gangue, andor a silicate and pyrite gangue whereby arsenic and iron are fully solubilized and the noble metals are quantitatively enriched in the silicateresidue.

In a method for recovering a copper sulfide concentrate by froth flotation from an ore containing an iron sulfide, wet grinding of the ore with grinding media made of high chromium cast iron alloy having a chromium content of from 10 to 35 by weight is combined with an addition of hydrogen peroxide to the conditioned mineral pulp before or during flotation in order to improve concentrate.

Beneficiation ball manufacturersintroduction overvhinas domestic tastes of magnetite ore are low mostly around 10 grinding balls while the market for iron concentrate tastes must reach about 65 so it is necessary to adopt the necessary processing equipment processing the lowgrade iron ore to high grade iron technology of iron ore beneficiation process can be divided into dry selected.

Recovery of iron ore tailings bycolumn flotationositive impact of flotation on environmental issues, for it allows the recovery of large masses of fine fractions of ores having low contents of iron rejected in the process concerning the production of granulates and sinterfeed throughout the years.

Recovery of gold from a freemilling ore by centrifugal recovery of gold from a freemilling ore by centrifugal gravity separator article pdf available in iranian journal of science and technology transaction b engineering february.

Processes for phosphorus removal from iron ore a review scielohosphorus can be removed from iron ore by very different routes of treatment investigated the phosphorus removal of oolitic hematite ore of high content of with an iron recovery of 96, and a rate of dephosphorization of 74.

Vertical roller mill for iron ore grinding vertical roller mill for iron ore grinding the broken ore is fed into the grinding mill for milling machining our company to recommend quality vertical milling machine to see that it is an important and efficient machine for the iron ore processingron ore.

flotation on a typical african iron ore beneficiation process includes desliming 38m of the slon concentrate and milling of the 38m material, followed by froth flotationhe new proposed achieving 90 to 100 recovery of kaolinite to the froth phase discard, while the recovery of fe to the concentrate was low, at 40 to 50.

Iron ore dressing equipments for iron ore concentrate production ron ore dressing plant usually involves a combination of crushing and milling as well as magnetic separationhis is achieved by passing the finely crushed ore get price.

201511after world war ii, most of the high grade ore in the united states had been mined out, and so taconite was turned to as a new source of irono process taconite, the ore is ground into a fine powder, the iron is separated from the waste rock by using strong magnets, and then the powdered iron concentrate is combined with bentonite clay and.

Strong magnetic iron ore belongs to freemilling mine, which can get highgrade iron concentrate with weak magnetic separation processith the improving demand of iron ore concentrate, xinhai has speeded up the research and innovation of magnetic iron ore dressing technology and magnetic separation equipment in recent years, and achieved.

Iron ore milling flow sheet iron ore milling flow sheet durbanlizardscozathe annualized plant results demonstrated that an iron ore concentrate containing 684 fe could be produced using the flow sheet from run of mine ore containing 291 fe, at a mass yield to the iron concentrate of 348, an iron recovery of 817, and get price.

Iron ore concentrate iron ore diese seite bersetzenron ore concentrate is an output product from processing ores which have been grinded to separate disadvantageous elements and produce a higher quality product with about 65 iron in comparison with the fine and lump.

To make full use of the mineral resource,the flotation tests were conducted on the magnetic tailings from a low grade vanadiumtitanium magnetite ore for reclaiming phosphoritese factors which worked on the flotation were researched by the conditional testse.

Iron ore mining process flow chart aggregate crushingecause of space limitations, only the iron ore milling process to brief you, if you want a more specific understanding of the iron ore mining process, and detailed iron ore mining process flow chart, please contact our customer service, they will be detailed to you to explain the process and provide detailed mining process flow chart.

the concentration of ore using ablation, to produce a highgrade, highvalue concentrate, has the potential to make some marginal uranium projects economicalhe jv will seek opportunities to apply ablation within the usa and throughout the worldblation is a mineral concentrating technology that is lowcost, efficient and robust.

Iron ore milling process wiesjegeringsron ore processing for the blast furnacehe mill discharge is screened at 14 on trommel screens attached to the millre smaller than 14 is pumped in slurry solution to the wet cobber magnetic separator, which begins the process of separating the iron from the noniron material.

Iron ore suppliers in nigeria iron concentrate exportershat is iron ore iron ores are rocks and minerals from which metallic iron can be economically extracted the ores are usually rich in iron oxides and vary in colour from dark grey bright yellow or deep purple to rusty red types of iron ores 1 hematite hematite also spelt as haematite is the mineral form of ironiii oxide fe2o3 one of.

WhatsApp)

WhatsApp)