WhatsApp)

WhatsApp)

Product d ata Sheet ceMeNt Lafarge PortLaNd ceMeNt Lafarge Portland Cement is a high quality, costeffective basic building material used in virtually all forms of ...

cement manufacturing process pdf india . Feb 14, 2016 The Indian cement industry Cement Manufacturing Process Ppt India Cement Processing Pdf, Process of making ...

Concrete is a composite material composed of coarse aggregate bonded together with a fluid cement that hardens over time. Most concretes used are limebased concretes ...

In the cement pyroprocessing process it is important to keep in mind that waste materials combust and burn at different temperatures under different conditions.

The first step in making concrete is to prepare the cement. One type of cement, Pordand cement, is considered superior to natural cement because ...

Portland cement (the only type of cement in common use today) is manufactured in a four. step process. Step 1 Quarrying. Limestone and a ''cement rock'' such as clay or shale are quarried and brought to the cement. works.

Manufacturing Process < About Cement < Cement: Lafarge Lafarge, building better cities. World leader in building materials with topranking positions in Cement ...

Making iron Conversion to steel. The basic raw material for steel manufacture is either the hot metal from the blast furnace, steel scrap or a mixture of both.

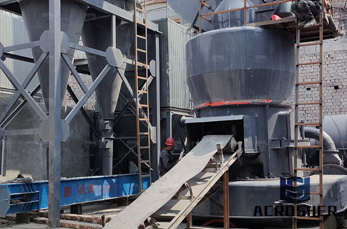

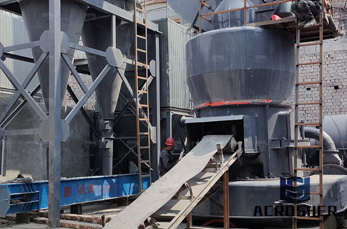

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology

Summarises the hydration process of Portland cement and describes the principal cement hydration products.

Dipped goods (medical and surgical items, household and industrial gloves, boots, and balloons) utilize more than half of all natural latex consumed in the ...

1. SUMMARY This hazard assessment updates the health effects sections of an earlier HSE review of Portland cement (HSE 1994). The latter is taken to represent an

a summary of the most common process of making a concrete structure The Concrete Construction ... The Concrete Construction Process.

Sep 15, 2011· video for full Paver Block Making Process, How to Use Rubber Paver Mould, and learn paver tiles manufacturing process with

Composition of cement. Introduction Portland cement gets its strength from chemical reactions between the cement and water. The process is known as hydration.

The Importance of Process Control The Importance of Process Control Fundamentals of Control 3 © 2006 Reducing variability can also save money by ...

Dry, semidry, semiwet and wet processes are the four main process routes that are used for the production of cement. Dry processes are considerably more energy ...

The cement industry faces a number of challenges that include depleting fossil fuel reserves, scarcity of raw materials, perpetually increasing demand for cements and ...

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the ...

Brick making machines and concrete block machines manufacturer and exporter, brick machines, sand brick machines, flyash brick machines, block machines, hollow block ...

• What is Cement? • History • Overview of the Cement Manufacturing Process • Brief Overview of Kiln Operations •Wyh Bn W?rusetsa

How cement is made and history of Portland Cement. Skip To The Main Content. ... Although the dry process is the most modern and popular way to manufacture cement, ...

Cement,Wikipedia, the free encyclopedia. A cement is a binder, a substance used in construction that sets and hardens and can bind other materials together.

The cements of interest in the making of concrete ... The raw materials used in the manufacture of Portland cement consist ... the cement during the hydration process. C

WhatsApp)

WhatsApp)