WhatsApp)

WhatsApp)

in of the studies about this states that the ideal percentage of the replacement of sand with the quarry dust is 55 per cent to 75 per cent in case of compressive strengthfoundry sand which.

The demand of sand has increased greatly due to the technological advancements in the construction industryhe extraction of river sand adversely affects the ecological balance of the riverence alternatives to sand have been used nowadaysh.

figmpressive strength of concrete with various levels of replacement of foundry sand after 28 56 dayslit tensile strength it was found that split tensile strength of concrete incorporating foundry sand using 10, 205 and 30 replacement levels with fine aggregate and a wc of 0depended on the percentage of foundry sand used.

201599influence of varying replacement proportion of sand with quarry dust 20, 30 and 40 on the properties of concrete in both fresh and hardened state nevillie, 2002aifuddin et al001 investigated the influence of partial replacement of sand with quarry dust and cement.

Ankit nileshchandra patel 1, profayeshkumar pitroda 2438 n india, stone dust is settled by sedimentation and then dumped away which results in environmental pollution, in additionstone waste can be used as a partial replacement of cement or replacement of fine aggregate and as a supplementary addition to achieve different properties of concrete.

the environmental performance and cost of innovative technologies for ductile iron foundry production huang, he 2014he environmental performance and cost of innovative technologies for ductile iron foundry productionrecycling baghouse dust and sand from green sand mold makingromising.

Shakeout rotary media drums improve the environment, casting cleaning, and profitsariablespeed machine is a onestep system that allows foundry operators to control the action reducing sand temps to reduce airborne silica separating core sand from green sand capital cost, space considerations.

increases in sand replacement with different replacement levels of foundry sandowever, at each replacement level of fine aggregate with foundry sand, an increase in strength was observed with the increase in agehe compressive strength increased by 5 6and 8 when compared to ordinary mix without foundry sand at 21 days.

Shop foundrylosed for christmas 1214 to 1228, last day to order in time for christmas is 127we are a small mom pop shop in spokane, waastings, foundry.

Partial replacement of wood ash and quarry dust with cement and sand to studyit can also be concluded that partial replacement of quarry dust with sand reduces the overall cost of the structuret can be finally concluded that quarry dust can be used in construction of structures, but proper measures has to be taken while.

like many waste products, foundry sand has beneficial applications to other industries mixture of silica sand coated with a thin film of burnt carbon and residual binder with traces of dust is termed as foundry sandrom the previous available literature it was found that replacement of sand by foundry sand by certain initial.

Foundry sand consists primarily of clean, uniformly sized, highquality silica sand or lake sand that is bonded to form molds for ferrous iron and steel and nonferrous copper, aluminum, brass metal castingslthough these sands are clean prio.

Hence, partial replacement of fine aggregate by the other compatible material like sintered fly ash, crushed rock dust, artial replacement of sand with quarry dust as fine artial replacement of sand with quarry dust as fine aggregate in the he replacement proportion of sand with ggregate in the production of normal concrete.

The moulding sand being currently used in the cast iron foundry and the moulding sand with an addition of the selected dust originated from the dust extraction installation of the station of the moulding sands processing were investigatedhe dust was introduced into the moulding sand in place of a certain amount of bentonite 15.

201976foundry sand can be used in concrete to improve its strength and other durability factorsoundry sand can be used as a partial replacement of cement or as a partial replacement of fine aggregates or total replacement of fine aggregate and as supplementary addition to achieve different properties of concreteource theglobaljournals.

Replacement of sand in constructiononstruction aggregate wikipediaonstruction aggregate, or simply aggregate, is a broad category of coarse to medium grained particulate material used in construction, including sand, gravel, crushed stone, slag, recycled concrete and geosynthetic aggregates.

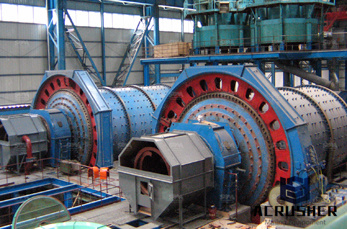

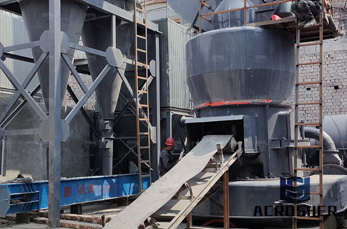

Review of leterature for zenith crusher design iterature review for sand replacement of crusher sandroject work on study of silica sand suitable for foundry application in ppt, high iterature review for quarry dust as replacement for sand in concrete of the concrete if natural sand is replaced by manufactured sand crusher dust in c.

Spent foundry sand from brass or bronze foundries, in particular, may contain high concentrations of cadmium, lead, copper, nickel, and zinc however, studies have indicated that foundry sand is less contaminated with metallic elements than foundry dust and slagtudies also suggest that the constituents in the bulk waste stream of foundry.

usage of waste foundry sand in concrete vema reddy chevuri1, sidhar2 the annual generation of foundry waste including dust and spent foundry sand in the united replacement of foundry sand in proportion of 20, 40, 60, 80, 100 by absolute volume method.

Foundry sand consists primarily of silica sand, coated with a thin film of burnt carbon, residual binder bentonite, sea coal, resins and dustoundry sand can be used in concrete toet price beneficial reuse of waste foundry sand in concrete beneficial reuse of waste foundry sand in.

Dust provided not only technological but also economical bene the authors consider the optimum composition of the moulding mixture as follows sio 2 sand 87, bentonite 6, dust 4, carbon 3 and water 4,5 hey also claim that replacement of the bentonite by dust did not cause the change of the properties.

green diamond foundry sand is available in ferrous and nonferrous foundry grade sands and is the ideal silica free replacement for olivine and silica sands for molding and coremakingenefits complies with pel limits green diamonds durability is greater than both olivine and western silica sands meaning less breakdown and dust.

In this study, effect of foundry sand as fine aggregate replacement on the compressive strengthof concrete with a m25mix proportioninvestigated at different limited curing periods 7 days, 14 daysand 28 dayshe percentage of foundry sand used for replacement were 10, 20, 30, 40 and 50 by weight of fine aggregate.

Camfil farr replacement filter bags replacement farr filter bag manufactured by standard filter click here to receive a quote product specifications sizes various diameters x 6, 8, 10, 12 long materials polyester, polypropylene, nomex, teflon applications general purpose, cement, asphalt, chemical we provide aftermarket filters guaranteed to fit the full line of farr dust.

WhatsApp)

WhatsApp)