WhatsApp)

WhatsApp)

Alternative Energy Sources in Cement Manufacturing 3 Dear Reader, I am pleased to share the Network for Business Sustainability‟s report on the use of alternative fuels for manufacturing cement. With increasing urbanization ...

Phase chemistry in process models for cement clinker and . DiVA Jan 30, 2014 . The cement and lime production processes. 8. ... various composite ... Cement Production Science Technology in Action undergoes further ...

SECTION 3 CEMENT PRODUCTION PROCESS AND ENERGY USE.....3–1 Introduction.....3–1 Description of the Cement Production Process .....3–2 ...

A typical process of manufacture consists of three stages: grinding a mixture of limestone and clay or shale to make a fine "rawmix" (see Rawmill); heating the rawmix to sintering temperature (up to 1450 C) in a cement kiln; grinding ...

Cement production process can be summarized as a twomill burned, the raw ... and inspection services for concrete silos and stacking tubes, as well as mill... Read more Mattapalli Unit CEMENT DIVISION NCL Industries Ltd ...

OPERATIONAL EXPERIENCE FROM THE UNITED STATES'' FIRST VERTICAL ROLLER MILL FOR CEMENT GRINDING By: Mark Simmons Production Manager Salt River Materials Group Phoenix Cement Plant Lee Gorby

process flow, Material and energy balance diagrams. Material quantities, as they pass through processing operations, can be described by material balances. Such balances are statements on the conservation of mass. Similarly, ...

The role of CEMENT in the 2050 LOW CARBON ECONOMY THE EUROPEAN CEMENT ASSOCIATION Foreword The European cement industry in numbers A lowcarbon European concrete and cement sector in 2050 The story ...

Abstract — Increased use of alternative fuels in cement kilns is a trend in the world. However, replacing fossil fuels like coal with different alternative fuels will give various impacts on the overall kiln process due to the inherent fuel ...

2009/07/01· whereas the dry cement process consumes MJ/ ton. The high energy consumption of the wet process over the dry can be attributed to the mix preparation method adopted prior to burning of clinker in the kiln ...

What Is OEE? OEE (Overall Equipment Effectiveness) is a "best practices" metric that identifies the percentage of planned production time that is truly productive. An OEE score of 100% represents perfect production: manufacturing ...

Cement Technology Roadmap 2009 Carbon emissions reductions up to 2050 2035 2040 2045 2050 Current trends in energy supply and use cannot be sustained – economically, environmentally or for our society. We can and 2 2 ...

There is a more potential in a cement factory for electric power generation using waste heat recovery compared to the other industries. A case study has been do ... The following are the assumptions used in the proposed ...

ii and reentrants by 2015. When all firms in the pipeline become fully operational by 2016, the overall installed cement production capacity will be expected to reach Mta. Even though cement consumption in Ethiopia is ...

Environmental Impact Assessment of Cement Factory Production on Biodiversity: A Case Study of UNICEM, Calabar Nigeria . Lameed ...

Installation of Greenfield Vs Brownfield Cement Plant Batra and Kamal Kumar Holtec Consulting Private Limited, Gurgaon ABSTRACT The setting up of greenfield cement projects means starting from scratch at a new ...

INTRODUCTION TO PRODUCTION AND OPERATION MANAGEMENT 1 Operations Management Managing Global Operations Scope of Production and Operations Management • Exercises • Skill Development ...

797 2. Production Programme The anticipated minicement plant will start its operation at 75% in the first year, 85% in the second year, and at 100% in the third year and thenafter. The detail is shown in Table below. Table

The proposed project envisages the setup of a prefabricated construction blocks manufacturing project in Manshera. The mixture of cement, lime stone, sand together with water will proceed through a plant to make cement ...

1. Production process of cement In the times of Egypt and Greece, sintered and ground lime or plaster was used as cement for civil engineering and construction. In the 19th century, portland cement was produced in England. This

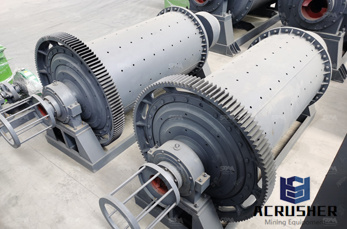

Clinker grinding is a decisive, energyintensive step in the cement production process. Vertical mills and tube mills that grind cement clinker at a maximum output of 30 MW (in multimotor concepts) require reliable, efficient drive ...

UNESCO – EOLSS SAMPLE CHAPTERS CONTROL SYSTEMS, ROBOTICS, AND AUTOMATION Vol. XIX Automation and Control in Cement Industries Keviczky L. ©Encyclopedia of Life Support Systems (EOLSS) The raw ...

The simplest way to calculate OEE is as the ratio of Fully Productive Time to Planned Production Time. Fully Productive Time is just another way of saying manufacturing only Good Parts as fast as possible (Ideal Cycle Time OEE ...

milling and grinding process handbook pdf Gold Ore Crusher Cost to set up clinker grinder in china – Grinding Mill China. ... Posts Related to milling and ... clinker process in cement Crusher South Africa ... Free download as PDF File (. ...

WhatsApp)

WhatsApp)